In 1951, the United States Army began publishing PS Magazine. The idea was to create a magazine about preventive maintenance that soldiers would want to read. They decided the best way to accomplish this was through eye-catching illustrations. They found an artist named Will Eisner, who believed comics could be used as a learning device. With this dedication and a group of talented artists by his side, Eisner’s company began hand-drawing the artwork for the magazine.

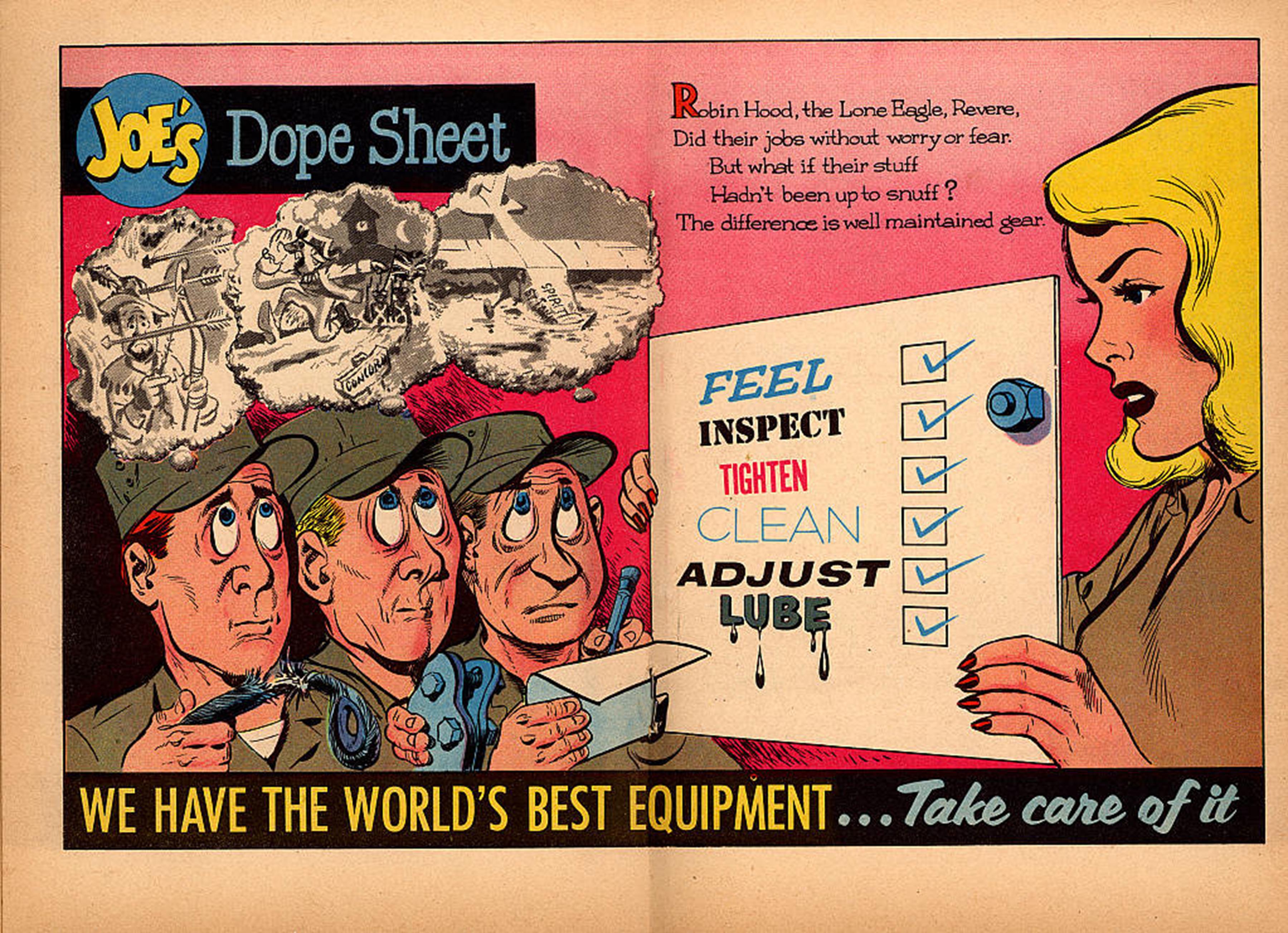

Each month contained a single-frame comic called “Joe’s Dope Sheet” and an accompanying limerick. Every issue follows the story of Joe, an Army soldier who ignored preventative maintenance practices, only to learn of its importance in the end.

One perfect example of this, shown above, comes from the August issue of 1957. The depiction affirms that checklists don’t have to be complicated or detailed to be extremely effective. Instead, they should be used as a reminder, or “brain-tickler,” to help maintenance professionals remember to verify that equipment is being well-maintained and kept in good working condition.

I’ve been reading a great deal of information about Industry 4.0, the Industrial Internet of Things (IIoT), Artificial Intelligence, Machine Learning, Digital Twins and other smart technologies. While I do think there are applications where this high level of analytical rigor is appropriate, I believe there’s still plenty of room for the basic tools. One of those fundamental tools is the preventive maintenance (PM) checklist.

Checklists have been used in a wide variety of industries (such as surgery and air travel) and in applications with different criticality levels. They seem to be everywhere you look, and while they may be intuitive and something you feel very familiar with, through experience and research, I’ve learned there are many ways to perform them incorrectly or apply them in an inappropriate situation.

PM checklists can be a valuable tool in your reliability and maintenance arsenal, and although there are multiple ways to carry out a checklist (we’ll cover this later), there are a few base ways they can be applied to your working environment:

- They can be added to your computerized maintenance management system (CMMS) as a list of tasks in a PM or procedure.

- They can be printed, laminated and attached to a clipboard.

- They can be attached directly to the equipment on a dry-erase board.

Checklist Types

There are two basic kinds of checklists to consider — the DO-CONFIRM and the READ-DO. The position of the “DO” in both of these is what fundamentally makes them different.

DO-CONFIRM: This is a checklist where the steps are not necessarily complicated and are mostly done from experience or memory. The list serves as an important review checkpoint to ensure nothing was missed or skipped.

READ-DO: This is a checklist that includes detailed steps necessary to complete the work. The list acts as a set of instructions, much like an assembly sheet you receive when buying furniture, especially in situations where performing the steps out of order or entirely missing one could result in an extremely negative outcome.

To help you understand the difference and see some examples, the table below lists different maintenance-related activities and the type of checklist that I would suggest.

A Checklist for Checklists

The steps below are loosely based on a similar graphic from Atul Gawande’s “The Checklist Manifesto,” which should be required reading for anyone wanting to develop checklists. There are three steps to developing a quality checklist — develop, draft and validate.

Developing:

Before beginning to develop a checklist, think about what your objective should be. Ask yourself:

- Are you using the appropriate type of checklist for the activity?

- Is the checklist highly complex?

- Does the checklist cover multiple areas of the plant, or can it be completed standing in one place?

The answer to these questions may drive you to choose one style over the other in order to adequately meet your demands.

If you’re using the checklist as preventive maintenance, be sure that each step is directly related to a known failure mode of the machine. This may require performing a Failure Modes, Effect and Analysis (FMEA).

Failure Mode and Effective Analysis (FMEA)

A step-by-step process for anticipating things that could go wrong during the design stage by identifying all possible failures in the design, manufacturing and assembly process.Source: reliableplant.com

An example of a checklist step utilizing preventative maintenance practices would look similar to this:

SYSTEM: Wire feed system

FUNCTION: Maintain proper wire tension across rollers

EQUIPMENT: Clutch

FAILURE MODEL: Seizes due to plate corrosion

FAILURE EFFECT: Wire breaks and shuts down sheeter

CHECKLIST STEP: Verify wire feed clutch is operational and maintains wire tension between XX and XX.

At this point in the checklist creation process, it would be wise to consider the frequency of the checklist. As these failure modes start to come into focus, make sure the performance frequency is aligned with the facility’s ability to catch a failure early enough to ensure equipment is still operational. This allows enough time for corrective maintenance to be scheduled and for the issue to be corrected before serious consequences can occur.

It is recommended to use this development period to discuss the checklist with other departments or groups to get their input on the specific steps included. It is also a great time to discuss how the completion of the checklist steps may impact their work routines or schedules.

Drafting:

Now that the steps are starting to come together, it’s important to make sure that the checklist is logical and user-friendly. To achieve this, consider aspects such as:

- Breaking the checklist into sections.

- Keep each section small enough to be completed from one general location without much movement required.

- Use consistent terminology and phrasing to maintain continuity.

Some popular terms and their meanings to consider implementing in your checklist can include:

- Verify: Ensure an action is completed

- Check: Look at something casually

- Inspect: Look at something closely, usually performed by a trained individual or using a specific standard

- Visually Check or Inspect: Observe without making contact

- Manually Check or Inspect: Observe and complete action using hands or tools

For example, specific action steps including these terms might look like this:

- Verify air pressure is between 35-45 psi

- Inspect chain sprocket for damage or hooking

- Visually check to ensure that all fasteners are present

- Manually check that piping is secure and stable

It is also important to make sure that the intended outcome or response is clearly stated within each step. For example, instead of saying, “Inspect the belt,” clarify it to say, “Inspect the belt for proper tension.”

Lastly, I have found that using a consistent positive or negative outcome can help with understanding when performing the checklist steps. For example, have each step either looking for a positive condition (using terms such as “intact”, “present”, “tight”, “full”, etc.) or a negative condition (using terms such as “broken”, “missing”, “loose”, “empty”, etc.) to avoid switching back and forth between the two. Having a consistent tone within each step helps the person using the checklist understand what outcome is expected from their actions.

Validating:

Once you have created a checklist that you and your team are happy with, it’s time to ensure the checklist is delivering the intended outcomes.

To verify this, have the checklist reviewed by individuals who regularly perform the tasks to make sure all the steps are logical and correct. It is also wise to give the checklist to someone who doesn’t normally perform the work. Their input can help ensure the checklist makes sense, isn’t too complicated and clearly accomplishes the objective.

Now would also be a great opportunity to record the amount of time it took to complete the checklist so the data can be used for future planning and scheduling efforts.

Checklists vs. Training

At this point, it might be tempting to just publish the checklist and let teammates start working with it, but putting the list into use prematurely can lead to new users modifying the checklist, usually in an overly detailed manner that often runs counter to the intended purpose of the list.

These types of changes go against the general purpose of these checklists – being a reminder or assurance that significant steps aren’t missed. Just as using a pre-flight checklist for a plane probably wouldn’t provide enough information for an untrained pilot to take off, most DO-CONFIRM checklists won’t be enough to properly meet the checklist’s objectives.

That’s why I strongly encourage you to create more detailed training documents or standards to go along with the checklists. These documents can be used during onboarding or training, and then the checklist can serve its purpose as a reminder tool instead of having to act as both.

Parting Thoughts

As the Army discovered through its magazine, simple is effective, and checklists are no exception. They are powerful ways to ensure the most important steps of a procedure or process are completed as intended, and great checklists help build confidence in even the most junior of technicians.

With the industry evolving faster than ever to meet the growing demands of its customers, it’s important to have an exceptional checks system in place to guarantee the quality of both the work being completed and the final product being produced.

By going back to the basics, we can help build a stronger foundation for the future.

Bill Barto will be a featured speaker at the 2023 Reliable Plant Conference and Exhibition.