Misalignment of an asset happens, and everyone has their method, process, and belief on how to resolve it. At that point, industry standards and proven techniques take a back seat to partial training and the midnight garage mechanic mentality and ingenuity. In some cases, the tribal knowledge method works, but for how long?

Misalignment assists in the destruction of products, profits, and "having a good day" in any facility in every industry. From assembly errors to infant mortality, many factors contribute to misalignment, including:

- A lack of knowledge

- Missed steps

- Unfollowed procedures

- Ignoring Original Equipment Manufacturer (OEM) requirements or specification

- Incorrect tool selection

What is Shaft Misalignment?

Shaft misalignment is defined as "A condition where the rotational axis of one shaft is not aligned with the rotational axis of the opposite or parallel (mating) shaft." When these two shafts reach a distance that has them out of a specified tolerance, they are determined to be misaligned.

Shaft misalignment can lead to increased wear and tear of machinery components, reduced efficiency, vibration, noise, and ultimately, premature failure of the equipment.

Types of Shaft Misalignment

There are three types of shaft misalignment: offset (parallel), angular, and combined.

- Offset misalignment involves the shafts not being in the same plane, leading to the offset or lateral misalignment.

- Angular misalignment occurs when the axes of two connected shafts are not parallel and form an angle with each other.

- Combined misalignment is a combination of angular and offset misalignment, in which the shafts are misaligned in angle and offset from each other.

What Causes Shaft Misalignment

A variety of factors can cause shaft misalignment. One common cause is installation errors, where machinery is not properly aligned during assembly. Additionally, thermal expansion due to temperature variations can lead to unequal expansion or contraction of shafts, resulting in misalignment.

Excessive loads or forces on the shafts can cause shaft deflection, bending, or misalignment over time. Wear and tear on components such as bearings or couplings can also contribute to shaft misalignment issues. Even foundations and baseplates can lead to misalignment, as can excessive vibration within the system.

Other factors that can play a role in causing shaft misalignment problems include:

- Manufacturing tolerances

- Inaccurate components

- Design flaws

- Pipe strain

- Case distortion

- Human error

Shaft Alignment Fundamentals

Shaft alignment fundamentals involve precisely aligning rotating machinery components to ensure optimal performance, efficiency, and longevity. Proper shaft alignment aims to align the rotational axes of coupled shafts to minimize misalignment, which can lead to increased wear, vibration, and premature failure of equipment.

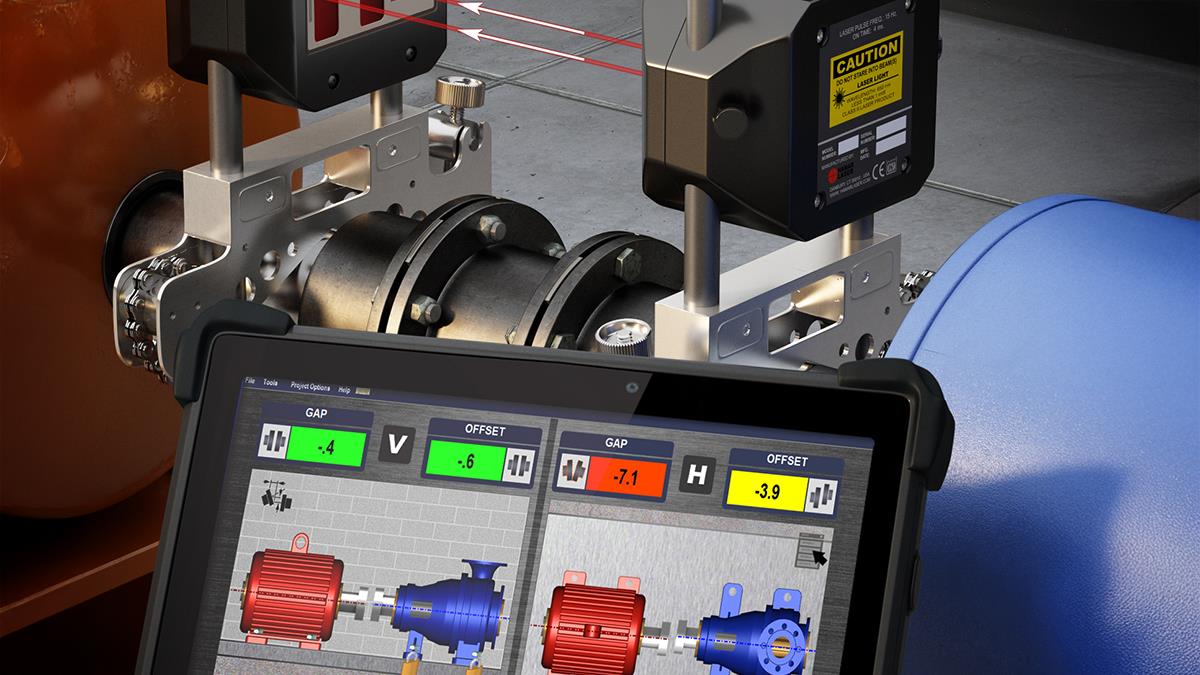

Key principles include achieving parallel alignment for the shaft to be in the same plane and granular alignment to ensure they are parallel. Common alignment methods include using laser alignment tools, dial indicators, and alignment software to measure and adjust the shafts' position accurately.

Regular maintenance and monitoring of shaft alignment are essential to prevent issues and ensure smooth operation of rotating machinery. By adhering to alignment best practices and manufacturer guidelines, maintenance personnel can optimize rotating machinery systems' efficiency, reliability, and longevity.

Alignment Best Practices

Some alignment best practices include regularly conducting alignment checks, especially after installation, repairs, or maintenance activities, to ensure the rotating machinery components are correctly aligned. Precision alignment tools such as laser alignment systems or dial indicators can help achieve accurate alignment.

Following the equipment manufacturer's guidelines and specifications for alignment procedures is important. Additionally, addressing any misalignment issues promptly can help prevent further damage and improve the overall efficiency and reliability of the machinery.

Proper training of maintenance personnel on alignment techniques and practices is also crucial for achieving and maintaining optimal shaft alignment. Having the latest technology to identify when a machine system is misaligned is only half the battle; getting it aligned accurately and precisely is the other half that industries still struggle with.