A Day in the Life of a Maintenance Planner

Maintenance planning provides the productivity piece of maintenance and increases your workforce without hiring additional staff. But what exactly does a planner do?

This narrative illustrates a day in the life of a maintenance planner and the principles they use along the way. When applied properly, these principles help maintenance teams in high-performing organizations successfully plan maintenance activities, drive productivity gains, and achieve a world-class standard of maintenance work.

What is Maintenance Planning?

Everyone on the maintenance team has a mission; the planner’s mission is to complete job plans. Notice this doesn’t say the jobs must be perfect – this is an impossible task. Instead, planners should use the Deming Cycle, in combination with craft feedback and other available information, to produce better plans as time goes on.

Deming Cycle

A four-step continuous improvement process that teaches the skills necessary for improving maintenance operations and plans. The four steps are Plan, Do, Study, and Act.Source: Reliable Plant

By avoiding perfection, planners effectively manage their time and create plans for the majority of jobs while seizing opportunities for growth and improvement.

But, to support a better system, plants must not prioritize reactive work over planning – this is a critical mistake. Planners must complete job plans, not support a reactive system.

Planning Reactive Work

Maintenance planner David arrived at work looking forward to helping the maintenance department boost its productivity and perform higher-quality work over time (the purpose of planning) through planned work orders.

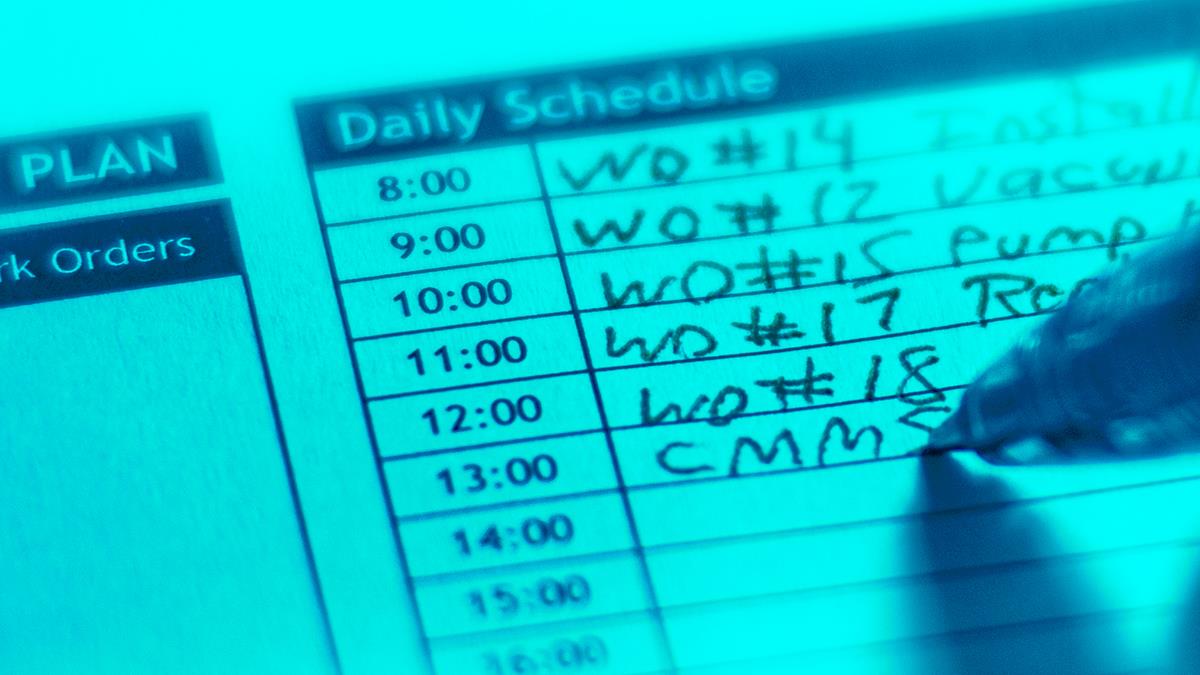

After checking his email, David opened the Computerized Maintenance Management System (CMMS) and found seven new WPLAN work orders (this status implies a work order system – a critical tool for planning). There was a mix of reactive and proactive work orders, and David could quickly identify which were reactive due to their priority ranking of P1.

While there were only two P1s – rusted steps and a noisy pump – David also had two P2 work orders for clogs and leaks. David considered these reactive because he knew his supervisors wouldn’t want to wait long for them to be completed. If possible, a planner should prioritize a supervisor’s work order requests.

Before planning the reactive work orders, David called the crew supervisor, Terry.

David: “Are you going to work either of the P1 work orders today?”

Terry: “We’ve started on the pump since it was making so much racket, but we won’t fix the steps until tomorrow.”

David: “Did you also see the two P2s for the caustic leaks and the clog on the polisher underdrain?”

Terry: “We’ll be able to start the caustic leaks today, but not the clogged underdrain.”

David: “Okay, thanks. I’ll knock out plans for the jobs you won’t start today.”

David needed to plan the two remaining reactive work orders immediately. His process for creating work orders was:

- Look for a work order history.

- Investigate the job’s scope.

- Create a plan.

The only time this process wasn’t followed was with emergency jobs labeled as P0. Thankfully, there were no emergency jobs in the CMMS.

To begin, David printed out each job to take notes with. Then he looked for an existing job history or plan. The P1 job for WO #16 was a simple welding job to repair a stairway. There wouldn’t be any history or job plan for something of that nature.

WO #15 for the P2 clogged underdrain in a confined space had an existing job plan that had been improved previously. The job used to take two people 20 labor hours to complete, but someone had discovered that a single technician could perform this in 13 hours if a shop vacuum was equipped with a two-foot extension. This not only saved time but money in terms of attaining a “confined space” permit and having an extra team member present.

Next, David donned his Personal Protective Equipment (PPE) and performed a field inspection to scope both jobs, marking any nameplate data or special circumstances he encountered. He then visualized how he would approach completing the work if he was the assigned technician.

The stairway welding looked straightforward, but David noted the increased elevation and the need for a safety harness and tie-off. Next, he located the underdrain and performed a similar assessment. From this information and his personal experience, David had everything he needed to create the job plans.

Because of the saved plan in the CMMS, the underdrain job was already complete, however, the plan for the stairs would need to be created from scratch. David began by assigning two technicians 35 hours to complete the job and listed out the necessary tools – 20 feet of angle iron, galvanizing spray, a needle scaler, a wire brush, and a safety harness.

He then defined the job’s scope – “Remove steps, repair, clean stairwell, paint. If needed, replace steps – 105-foot elevation.”

Simple as it seemed, this was now a planned WSCHED job. In most cases, the technician doesn’t require a detailed procedure as much as the crew supervisor needs craft and time specifications to effectively manage his crew.

Planning Proactive Work

After a quick break, David concentrated on the three proactive WPLAN work orders. Two jobs were on pumps:

- Machining a pump shaft for inventory and a vacuum pump running hot.

- Installing a screen to protect wharf gutters.

For WO #17 on the pump shaft, David found the engineering drawing and the new part’s inventory number and created an equipment file for future use. Then David created the plan – “Fabricate new shaft per engineering drawing #103. Spec +/- 0.002 inches. Deliver to inventory as part PMP-HB-001.”

He estimated the job would take a machinist using a 2” X 48” 304SS two days to complete. Since the materials were non-stock, he ordered the part before changing the work order status to WPARTS.

Neither the gutter nor vacuum pump jobs had historical information, so David performed another field check. WO #19 for the hot vacuum pump was easy to locate with the supplied asset tag number.

After scoping out WO #29 for the wharf gutter screens, David concluded that only the drains should be screened so the gutters could effectively prevent river pollution, however, David was leery of plant design changes; not only was it inappropriate to change plant designs without approval, but simply looking into design changes could bog down a planner timewise. This way of thinking is critical to a successful Management of Change (MOC) process.

Management of Change

A process for preventing or mitigating business losses - including degradation of safety, health, or environment - as the result of changes made to how you construct, operate, manage, or repair your facility or processes.Source: Reliable Plant

To the engineer, the gutters were essential – while the drains were typically left open, during oil spills, staged plugs were quickly installed, preventing pollution. The engineer agreed to only screen the drains, but in a way that allowed technicians to quickly insert plugs.

David estimated two technicians would need 12 hours to complete the job using a hardware cloth and a rotating wire snack equipped with a cutting bit. He changed the work order status to WSCHED and went on his lunch break.

After lunch, David reviewed the Operations and Maintenance (O&M) manual for the vacuum pump. Fortunately, the manual included a troubleshooting section, which revealed that the issue was most likely a bad intake valve reed.

David wrote the job plan to inspect all intake valves and to take appropriate action where needed. He estimated the job would take a mechanic two days to complete before marking the job as WSCHED.

Receiving New Work Orders

David noticed four new work orders in the CMMS. Three were reactive P1s, and one was a P3 to upgrade a pump. He verified with Terry that the P1s hadn’t been started before designing the plans.

The three reactive work orders were:

- WO #32 – Potable water pump with high vibrations.

- WO #35 – Rusty union on a fire protection system.

- WO #36 – Drip on a wharf unloading arm.

The CMMS had existing plans for the water pump and the unloading arm; they revealed that the pump usually had a loose nut on the impeller and that, with a high lift, the unloading arm could be repaired without being disassembled. Unfortunately, there was nothing on the fire system.

David printed the work orders and went into the field. The potable water pump was exactly as described, and the unloading arm area was well-suited for the high lift. While the wharf needed to be cleaned (oil had dripped onto the deck during unloading), nothing had leaked into the water, meaning it wasn’t an emergency. David then found the rusty union and discovered that ten feet of piping also needed replacing.

David went back to his office and created the job plans.

For the pump, the plan included:

- Opening the inspection door.

- Checking the torque on the impeller nut.

- Re-machining the impeller threads, if necessary.

David estimated it would take a machinist and an assistant 16 hours to complete the job.

For the unloading arm, the plan included:

- Breaking the top flange using a high lift.

- Replacing the gasket on the arm flange.

- Cleaning greasy spots with degreaser and rags.

The job would take 16 hours for one mechanic to complete.

Finally, he prepared a plan to replace the union and rusted piping. It would take one technician two days to complete, and they would need:

- Two inches of union

- 20 feet of two-inch piping

- 18-inch pipe wrench

- A six-foot ladder

- A portable pipe machine

He also added a note for the technician to follow all standard cleaning procedures and to notify the proper authorities if necessary before he marked the plans WSCHED.

David had successfully planned 189 hours of work, meaning he was effectively planning for 19 technicians. However, he also needed to account for the unplanned and Preventive Maintenance (PM) work – ten hours for the caustic line leak and one hour for the pump noise – bringing the total to 200 hours.

Unplanned PM work typically accounts for 33% of all maintenance labor hours. This means that in addition to the nearly 190 hours of planned work, the facility could expect more than 60 hours of unplanned work. In effect, David was planning for more than 25 craftsmen.

On average, a planner can plan for 20 to 30 craftsmen, but at this ratio, there isn’t enough time for David to work on jobs in progress or other facility duties, such as managing small parts storerooms or handling purchasing duties. In an ideal world, David would be responsible for no more than 20 craftsmen.

Closing Completed Work Orders

After completing the new reactive work orders, David had an hour left in his day, so he began closing completed work orders.

Although David’s plant was transitioning to “mobile maintenance,” field technicians were still given printed work orders to execute jobs and record feedback. Once completed, these paper forms were given to the crew supervisors, who marked the job as COMP in the CMMS. This told the planner the job was ready to be closed.

David scanned the written documents for feedback on how the repairs were made, what delays were encountered, and what parts and tools were needed to complete each job. He also consulted the CMMS, which would show the total labor costs for each job based on the technicians’ timesheets. The CMMS also revealed the total cost of each work order based on the parts retrieved from the storeroom. This history cost information is crucial in helping to guide future repair and replacement decisions.

After making appropriate alterations to the job plans, David gave the printed work orders to the planning clerk, who inputted the written feedback into the CMMS and marked each work order as CLOSE.

Conclusion

At the end of his day, David reflected on the role he played in the plant’s high availability. The creation of a weekly schedule set a work goal and made the advanced coordination of other crafts and material staging possible.

Simply providing these work goals through advanced scheduling practices had helped the maintenance team boost its wrench time productivity to 55%, which was higher than the 35% industry norm. At 55%, 30 people were as productive as 47 team members operating at a 35% wrench time. They had essentially added 17 people to their workforce and achieved a higher caliber of maintenance work without having to hire any additional staff.

But to realize and sustain these results, planners must be devoted to their work and constantly plan, improve, and complete jobs.